- Morris/Austin J/JB/101 Register display

Total Pageviews

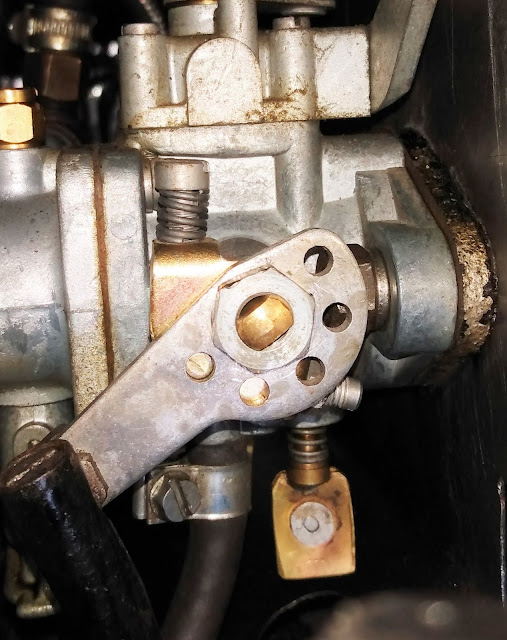

Solex Type 30 AHG -Volume Control Screw

11 October 2019

While setting up the carb I struggled to get decent access to the volume control screw. This has to be adjusted with a flat bladed screwdriver from beneath the carb. Heat shield has a hole for access but still difficult and hot!

Here is my solution...may not be the best but it works for me.

Took out the screw and turned it into a 'wing screw' by adding a brass wing.

Actually used two pieces of .033 inch brass strip pop rivetted together and separated slightly to be a good fit in the screw slot. Then soldered them in place. You could use a single piece of metal but the brass was what I had to hand.

Makes adjustment much easier as I can now turn the screw by hand and access is easier.

While setting up the carb I struggled to get decent access to the volume control screw. This has to be adjusted with a flat bladed screwdriver from beneath the carb. Heat shield has a hole for access but still difficult and hot!

Here is my solution...may not be the best but it works for me.

Took out the screw and turned it into a 'wing screw' by adding a brass wing.

Actually used two pieces of .033 inch brass strip pop rivetted together and separated slightly to be a good fit in the screw slot. Then soldered them in place. You could use a single piece of metal but the brass was what I had to hand.

Makes adjustment much easier as I can now turn the screw by hand and access is easier.

Rear Brake Shoe Adjustment.

May 2022

Rear wheel cylinder on offside brake now seized! Just lack of use, I guess.

Removed and replaced with new but had to make up length of new wheel cylinder with a 3.5mm spacer and new snail cam similar to the nearside setup.

When fitting the new unmodified wheel cylinder I could not get the brake shoes to lock on the brake drum even on full adjustment of the old snail cam!

Old wheel cylinder had an effective length of 58mm but new wheel cylinder was just 54.5mm.

Only difference this time was I glued in a metal spacer below the origin 'U' shape piece.

With the modified part and a new snail cam from MEV ( gave about 2mm more lift) all was good.

See photos.

Recently while balancing all the brakes to bite at the same time I couldn't get the nearside rear brake to bite hard on the drum, even when fully adjusted via the snail cam adjuster.

After checking for any brake drum reskimming or brake show wear I was still puzzled. Brake drums are still the original 9.00 inches diameter and the brake shoes are new. The snail cam adjuster was original, looking in good order.

Decided to check the offside rear brake setup, and all appeared the same but the adjustment here was good!

Overnight I recalled changing the nearside brake cylinder after one leaked. I had bought a new pair and still had one unused.

After checking the effective length of the nearside and offside brake cylinders I found the new one was 5 mm shorter than the other! Thus the adjuster needed to cope with an extra 5 mm of adjustment to get a hard bite.

Went back to the original supplier (MEV) and a second source and both confirmed the length at close to 55mm. The offside cylinder measured close to 60 mm!

MEV did suggest a new snail cam adjuster that they say is larger than the original to compensate for brake wear. Ordered this.

However in the meantime I removed the pressed metal bearing shoe stop (fig 1.) and made a new one from a piece of 8 mm square steel door handle spindle. Made the base 2.5 mm thicker at 4 mm (was 1.5 mm) and the sides 1.5 mm thick per the original. Made two centre punch marks each side of the new shoe stop, to hold it in place, and tapped it gently in place to hold.

Reassembled everything and it did make and improvement but the adjustment was still near the max.

Next day the new snail cam adjuster arrived and was clearly larger in size.

Fitted this and all was good. Now needs about 6 clicks to get a solid bite.

Didn't go back and take out my modified shoe stop....the new adjuster may work with the original shoe but there are only so many times I can remove and refit brake shoes...especially those beehive springs!! Anyone got a good alternative for those little perishers!

If you have a similar problem try the snail cam adjuster from MEV Spares first it may well do the trick.

Fig. 1 Shoe stop before removal...easily remove ...needs little force.

With shoe stop removed

Square bar from domestic door handle

|

| Modified Shoe Stop .. hacksawed and filed to shape. |

|

| Existing Snail cam adjuster |

Stoke Prior Steam Rally -Sept 2019

Rally Photos - Sunday 15th September 2019

A few shots from a day at Stoke Prior Steam Rally and car show.

Also found a companion British Railways vehicle in John Giles's superb Mechanical Horse Scammel.

A few shots from a day at Stoke Prior Steam Rally and car show.

Also found a companion British Railways vehicle in John Giles's superb Mechanical Horse Scammel.

Interior Additions

23 August 2019

Bought a nice British Railways Collico Services wooden folding box and after a couple of hours of work was as good as old! Still has original labels inside too.

Apart from being a period piece it is also useful for storing large items such as spare battery, oil, water and spares etc.

Also added a homemade book rack to hold some BR related books and booklets.

May add some BR vehicle models that I have collected...working on it!

Not much more to add unless someone has a spare small model railway they want to get rid of!

Bought a nice British Railways Collico Services wooden folding box and after a couple of hours of work was as good as old! Still has original labels inside too.

Apart from being a period piece it is also useful for storing large items such as spare battery, oil, water and spares etc.

Also added a homemade book rack to hold some BR related books and booklets.

May add some BR vehicle models that I have collected...working on it!

Not much more to add unless someone has a spare small model railway they want to get rid of!

Rear Door Rubber Buffers

11th August 2019

Rear door buffers

Decided to have a go moulding some rear door buffers as there doesn't appear to be any for sale anywhere.

Bought some silicon moulding rubber, made a wooden box from odd bits laying about and with a genuine rear door buffer, lent to me by Steve Parkes, made a mould.

Suspended the original buffer upside down in the box and filled the existing two fastening holes with wooden dowels and plasticine and the main cavity at the back of the buffer with plasticine. Left sufficient witness of fastening holes so they could be drilled out on the finished buffer moulding. (See blue silicone mould pic below.)

Used a 2 mix rubber moulding compound for the buffers. Measured the quantity needed to just fill the mould to the top surface without overflowing.(see pic below for 60 shore rubber used)

Had several goes until I got a couple of good ones. They all released from the mould very easily but the surface finish was not great. The surface was better if the rubber was mixed and poured very slowly. Never did get a perfect one before I ran out of rubber mix. Did get six from the amount of rubber used.

The consistency of the finished rubber was fine, quite hard but still flexible.

To finish off I then drilled out the fastening holes, with a conventional drill, leaving a step about 10mm from the base to suit a small washer, inserted from the top, for a screw head to bear against, to fix the buffer to the door. Also drilled the centre indent with a countersink tool to give it a bit more depth.

Finally to get a better finish I sanded and applied a flexible black paint finish. If the surface had been better I may have not painted.

Anyway fairly happy with the finished items. Still have the mould if any one wants to have a go?

Rear door buffers

Decided to have a go moulding some rear door buffers as there doesn't appear to be any for sale anywhere.

Bought some silicon moulding rubber, made a wooden box from odd bits laying about and with a genuine rear door buffer, lent to me by Steve Parkes, made a mould.

Suspended the original buffer upside down in the box and filled the existing two fastening holes with wooden dowels and plasticine and the main cavity at the back of the buffer with plasticine. Left sufficient witness of fastening holes so they could be drilled out on the finished buffer moulding. (See blue silicone mould pic below.)

Used a 2 mix rubber moulding compound for the buffers. Measured the quantity needed to just fill the mould to the top surface without overflowing.(see pic below for 60 shore rubber used)

Had several goes until I got a couple of good ones. They all released from the mould very easily but the surface finish was not great. The surface was better if the rubber was mixed and poured very slowly. Never did get a perfect one before I ran out of rubber mix. Did get six from the amount of rubber used.

The consistency of the finished rubber was fine, quite hard but still flexible.

To finish off I then drilled out the fastening holes, with a conventional drill, leaving a step about 10mm from the base to suit a small washer, inserted from the top, for a screw head to bear against, to fix the buffer to the door. Also drilled the centre indent with a countersink tool to give it a bit more depth.

Finally to get a better finish I sanded and applied a flexible black paint finish. If the surface had been better I may have not painted.

Anyway fairly happy with the finished items. Still have the mould if any one wants to have a go?

Ragley Classic Car Show

Monday 27th May 2019

Attended the Ragley Car show with my van YMJ 702. Changed the grill and rear badge to MORRIS, from AUSTIN, just for a change.

Arrived early, around 8:30am, to avoid the queues and drove straight in and parked in section 'L' for commercial vehicles. Was the first to arrive and as it turned out the only commercial vehicle in the section!

Awarded the 'Class Winner' trophy...how could I loose being the only one!

Met some nice people and had a lot of interest in my van.

Here are a couple of photos...there would have been more but my camera battery ran out of juice!

For the eagle eyed I have added the two rear door buffers since last out. Did this by making a silicon rubber mould of an original and casting with a black rubber compound. Turned out not too bad...right shape but surface has a few bubble marks.

Attended the Ragley Car show with my van YMJ 702. Changed the grill and rear badge to MORRIS, from AUSTIN, just for a change.

Arrived early, around 8:30am, to avoid the queues and drove straight in and parked in section 'L' for commercial vehicles. Was the first to arrive and as it turned out the only commercial vehicle in the section!

Awarded the 'Class Winner' trophy...how could I loose being the only one!

Met some nice people and had a lot of interest in my van.

Here are a couple of photos...there would have been more but my camera battery ran out of juice!

For the eagle eyed I have added the two rear door buffers since last out. Did this by making a silicon rubber mould of an original and casting with a black rubber compound. Turned out not too bad...right shape but surface has a few bubble marks.

|

| AUSTIN APACHE Made in South Africa |

Subscribe to:

Posts (Atom)

.jpg)